The Full Access truck tool box body is constructed from 1/8” diamond tread plate aluminum formed and fully welded into 413F cast aluminum alloy end plates. The pivot of both lid and base plates is machined to 7/8” and bronze bearings are pressed into the bores. The 3/4” pivot pin is machined from 18-8 stainless steel and is retained with a stainless steel washer and cotter pin.

In the closed position, wind-proofing flanges with weather stripping in both the lid and base castings contact each other to exclude wind-driven rain and snow. Weather stripping along the front and rear edges block rain and snow from entering.

The latch assembly is recessed and locks into a back plate (1/8” 5052 aluminum alloy) behind it. The latch pivots 90 degrees on stainless steel locking rods which ride in nylon bearings. When closing, the latch is rotated 90 degrees and the outer ends of the stainless steel locking rods engage lugs on the base casting, drawing the lid closed. Extra torque on the final few degrees of closing causes the rods to wind up slightly, resulting in a tight closure. The latch handle and the interior catch pivot on a 5/16” diameter stainless steel spring pin pressed into the 413 F cast aluminum latch body.

The latch handle, which moves independently of the latch body, releases an internal catch when pulled, and allows the latch body itself to pivot. The spring loaded catch automatically locks (clicks in place) when the latch body is pushed closed – movement of the latch handle is not necessary. The closing of the latch body also engages the center locking area, located at the base in front.

When the latch is opened the tool box lid remains closed. A slight upward force is required to initiate opening of the lid, and when opened approximately three to four inches, gas springs come in to play and open the lid the remainder of the way. The gas springs are positioned so that there is significant extra force available when the lid is open to ensure the lid always stays firmly open.

Mounting rails, made from 6063 aluminum extrusion, are located at the bottom and top of the inside rear wall and run the full length of the box. The rails contain T-slots which are sized to accept standard 1/4” - 20 carriage bolts. The upper rail incorporates a tray for small items and a vertical lip sized to accept size #1 and size #2 polypropylene bins.

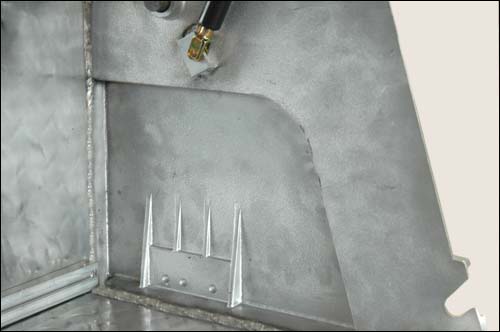

The box is mounted in the front using the three 5/16 x 1” oblong holes. The rear of the box is either suspended from above or supported from below through a heavily reinforced 1/2” thick cast area on the base ends. To facilitate drilling, 3 small drill point centering indents are located in the outside of the box which are aligned with 3 holes on the interior. Approximately 1/16” of aluminum separate the indent on the outside from the mounting hole on the inside of the box.